Automatic liquid fillers: complete guide

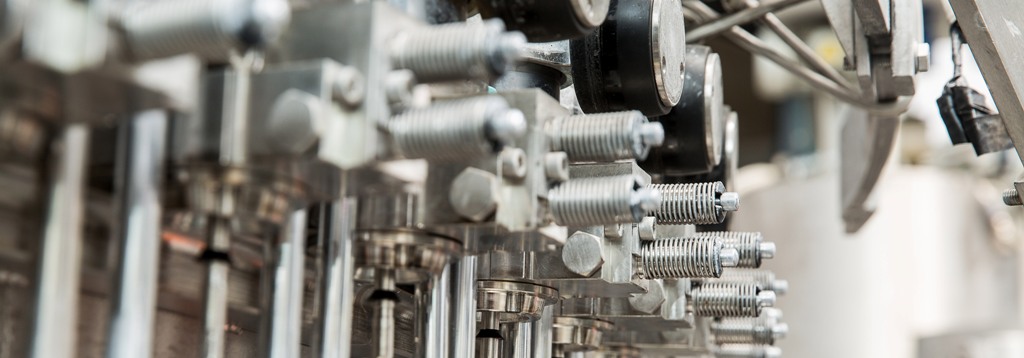

Automatic liquid fillers are the heart of bottling and packaging lines. Thanks to their precision, speed, and reliability, they are essential for companies in the food & beverage, cosmetic, chemical, and pharmaceutical sectors.

In this article, we will explore what fillers are, how they work, the main types available, and how to choose the most suitable solution. Finally, we will present BBM Packaging’s offer of used fillers from leading brands such as SIDEL, KRONES, Procomac, Simonazzi, and SACMI.

What filling machines are and what they are used for

Filling machines allow liquids to be dosed and placed into containers—bottles, cans, flasks, or other formats—automatically, hygienically, and precisely. They ensure consistent final product quality and reduce time and material waste.

Their operation varies depending on the type of liquid (water, carbonated drinks, oils, detergents, viscous liquids) and the technology used: gravity, pressure, vacuum, or volumetric.

Types of automatic fillers

1. Linear automatic fillers

Linear automatic fillers operate along a straight line, with containers moving on a conveyor belt. Ideal for medium-scale production, they offer great flexibility in format changes and handling different products. They are used for food, cosmetics, oils, detergents, and fruit juices.

2. Rotary fillers

Rotary fillers work continuously: containers rotate around a central carousel, allowing high-speed filling. Perfect for high-volume production such as mineral water, soft drinks, and beer, they ensure efficiency and uniformity.

Compatible containers and applications across different sectors

Modern fillers are modular and can be configured for numerous container types:

- Glass bottles – for premium beverages or temperature-sensitive products.

- PET bottles – lightweight and durable, suitable for high-speed lines.

- Cans – ideal for beer, energy drinks, and soft drinks.

- Plastic or HDPE flasks – used in the cosmetic and chemical sectors.

Features ensuring quality in fillers

- Filling accuracy: each container receives the exact amount of product, reducing waste and complying with regulations.

- Speed and efficiency: automating the process allows speeds of up to hundreds of containers per minute.

- Hygiene and safety: made with suitable materials (stainless steel) and CIP/SIP cleaning systems to meet strict hygiene standards.

BBM fillers: used, guaranteed, and customizable

BBM offers a wide selection of used automatic liquid fillers, fully refurbished and configurable according to customer needs.

The catalog includes PET and glass bottle fillers from major brands: COBERT, GANGLOFF, KRONES, SACMI, SIMONAZZI, SIDEL, and Procomac.

Three options are available:

- As-is: economical and immediate solution.

- Refurbished and guaranteed: inspected by BBM technicians with an efficiency guarantee.

- Ready-to-use with compatible spare parts kit: turnkey machines, ready for production.

Each machine can be customized for product, format, cap type, or level of automation. BBM specializes in fillers for still and sparkling water, soft drinks, and beverages, suitable for lines of any size and complexity.

Why choose BBM

- Extensive experience in the filling and packaging sector.

- Wide immediate availability of machines from top brands.

- Technical support and personalized consultancy.

- In-house refurbishment and remanufacturing service for quality and reliability.

- Compatible spare parts always available.

BBM fillers optional features

- Assessment and removal of decommissioned filler

- Machine dismantling or relocation

- Installation and start-up at your site

- Format change

- Periodic maintenance

- Compatible spare parts kit for self-maintenance

- Technical training for operators

- HOTLINE package for remote assistance

- Thread conversion, nitrogen system

- Level and cap inspector, machine enclosure

- Air ionizer device and dust extraction

They often include PREMIX, CIP, rinser, and capper from brands like AROL or ZALKIN, for a complete ready-to-use line. BBM also developed UNICOM, the first universal module that allows a blower to connect to a filler from any manufacturer, even if they are different from each other.

This machine eliminates air conveyor belts for transporting bottles between machines, solving all related issues.

FAQ on automatic filling machines

- What is the difference between a linear and a rotary filler? Linear fillers are flexible, ideal for medium production and frequent format changes. Rotary fillers handle high volumes at very high speed.

- Can I use the same machine for glass and PET bottles? Yes, many fillers can be adapted to different materials with dedicated components.

- Does BBM provide support and spare parts? Absolutely: we offer installation, testing, technical support, and compatible spare parts.

- Where can I view the catalog of available fillers? You can find the updated catalog here.

- Does BBM provide customizations for filling machines? Yes, we dismantle and refurbish all wear parts and offer upgrades to reduce consumption and costs.

- Do used fillers maintain the accuracy of new machines? Yes, especially choosing the “Refurbished and Guaranteed” or “Ready-to-Use” options.

Conclusion

Automatic liquid fillers represent a strategic investment to ensure quality, efficiency, and production continuity. With BBM, you have the assurance of reliable, refurbished, and customizable machines, supported by expert technical service and ongoing assistance.

🔗 Discover all our used rotary fillers.