BBM Packaging has recently completed the supply of a OCME Vega model X30V shrink wrapper to a company in Eastern Europe, active in the food canning sector.

The end customer, known for producing a wide range of products – from canned tomatoes to preserved vegetables, sauces, legumes, jams, juices, and bottled sunflower oil – required a reliable and flexible packaging solution suitable for various packaging types. For this reason, they chose to rely on BBM.

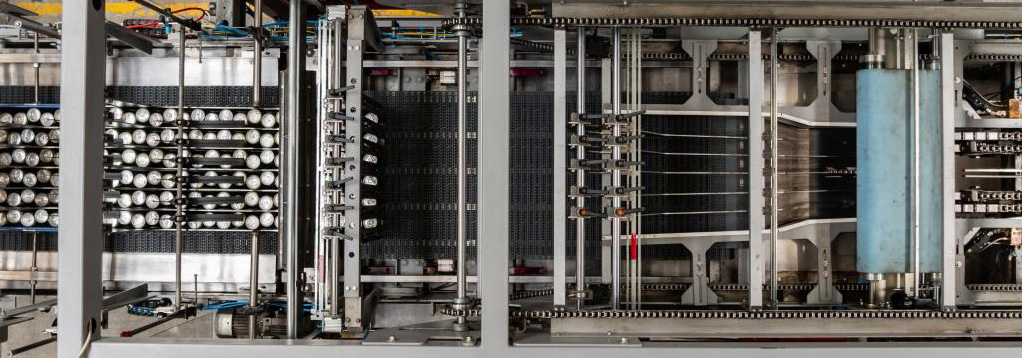

After a joint analysis of the requested specifications, BBM identified the OCME Vega X30V shrink wrapper as the ideal solution. The unit, built in 2004 with a right-hand operator side, was fully refurbished in our workshops and subsequently customized according to the customer’s production needs. This allowed the system to achieve the performance required to ensure continuity and reliability.

Main Features of the OCME Vega X30V Shrink Wrapper:

- High packaging versatility: the Vega X30V produces tray + shrink film packages on a single lane, suitable for cans, PET bottles, and glass bottles. It also adapts easily to different container types.

- Optimized logistic packaging: the tray is made from die-cut cardboard glued at the edges. These edges, often used for product branding, can have 90°, 45°, or rounded corners, offering flexible solutions for visual communication.

- Excellent accessibility: the design facilitates cleaning, maintenance, and format change operations, ensuring quick access to all components.

- Components compliant with the highest safety standards: the shrink wrapper uses quality parts selected for durability and operational reliability, reducing the risk of line downtime.

Performance and Customizations on the OCME Shrink Wrapper

- Tested format: the machine successfully passed tests for the 6×4 can tray + film format, one of the configurations most requested by the customer. Consequently, the line could start production immediately.

- Production speed: the Vega X30V operates up to 30 packs per minute, providing an excellent balance between efficiency and operational stability.

- Line integration: BBM installed an input conveyor with adjustable side guides, designed to simplify format changes while improving adaptability to different containers.

- Technical support: the supply includes the complete list of spare parts recommended, with original **OCME** electronic components. This ensures operational continuity and reduces machine downtime for the customer.

Delivery Timeline

BBM finalized the order in February and, in just three months, refurbished, customized, and delivered the machine in May. In addition, our team managed the entire shipping logistics, ensuring punctuality and integrity of the system upon delivery.

BBM Packaging Solutions continues to support food industry companies with tailor-made, reliable solutions designed to improve production efficiency. Our team is also available to provide consultancy and evaluate the most suitable solution for any production line.

If you are also looking for custom shrink wrappers and packaging machines for your company, contact us!

The team at BBM Packaging Solutions is ready to analyze your needs and recommend the most suitable technology.

Focus: OCME Shrink Wrappers

Used and refurbished OCME shrink wrappers and packaging machines are a practical and effective solution for companies looking to increase productivity without investing in new machines. These machines allow the packaging of single or multiple products, with or without cardboard or tray support, ensuring bundle stability and optimal finished pack aesthetics.

Thanks to the use of modern shrink films, it is possible to use environmentally friendly materials, reducing plastic consumption and improving the sustainability of the production process.

Purchasing used and refurbished OCME machines offers numerous advantages: lower costs compared to new machines, faster delivery times, and machines inspected and refurbished by our technicians to ensure consistent performance. Additionally, shrink wrappers integrate easily into existing packaging lines and can be adapted to specific layouts, speeds, and formats.

Available versions include machines with sealing bars, film launchers, or high-energy-efficiency shrink tunnels. All solutions guarantee ease of use, low maintenance costs, and fast format changes, making refurbished used machines an intelligent and cost-effective choice for companies.