In the automated bottling and packaging sector, having the ability to reproduce discontinued or damaged parts can truly make a difference.

BBM, specialized in providing compatible spare parts for the leading brands in the industry, offers a free reverse engineering service for part reproduction.

This solution allows the faithful recreation of mechanical and electronic components for blow molding machines, filling machines, packaging machines, labeling machines, cappers, end-of-line equipment, and much more—even when the original drawings are no longer available.

Thanks to our advanced technologies and in-house expertise, clients can receive a free, no-obligation evaluation before deciding whether to proceed with production.

What “reverse engineering for part reproduction” means

Reverse engineering involves analyzing, measuring, and modeling an existing component—even if damaged or incomplete—to create a digital model and reproduce it with high precision. Our free service includes:

- initial analysis and cost-free evaluation of the part to be reproduced;

- dimensional survey or 3D scanning of the original (or remaining fragments);

- creation of the corresponding 3D CAD model;

- customized quotation based on complexity and material.

Production of the component proceeds only if the client approves the quotation.

How the BBM Reverse Engineering Service works

When a client requests a reverse engineering operation, we follow structured and transparent steps:

- Submission of the part or basic information The client provides the original component, photos, preliminary measurements, material, and intended use.

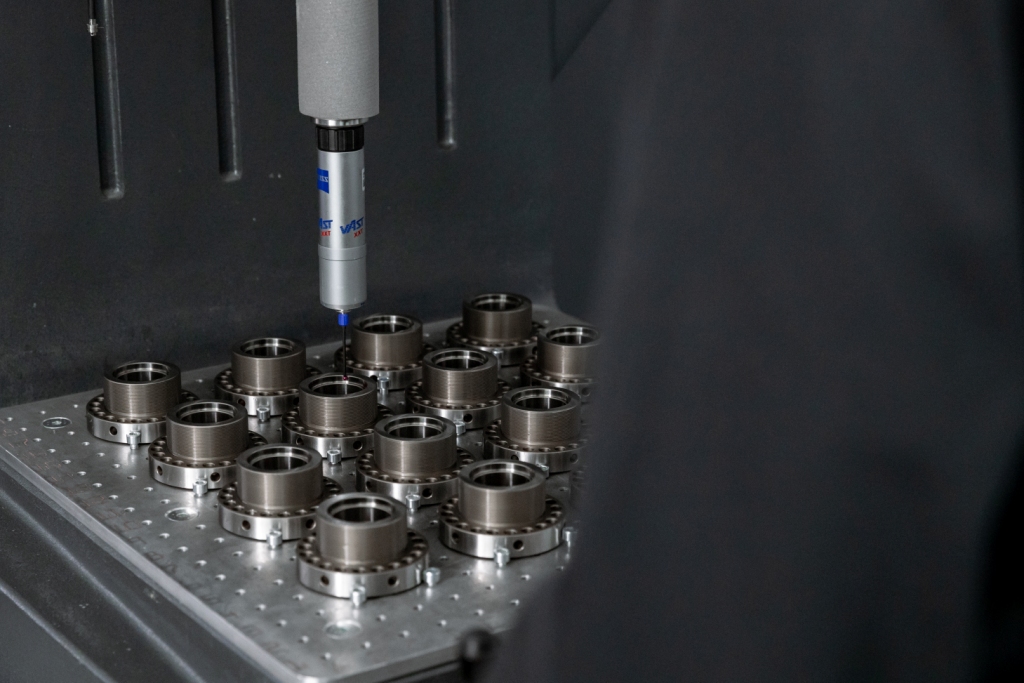

- Inspection, scanning, and dimensional survey We use extremely precise measurement tools—coordinate measuring arms, scanners, and lasers—to obtain the complete geometry of the part.

- Digitization and 3D CAD modeling From the collected data, we generate a three-dimensional model, calibrating tolerances and correcting any imperfections.

- Free, no-obligation quotation Based on the model, material, and production quantity (one or more parts), we prepare a transparent offer.

- Component production If the client approves, we manufacture the part using the most suitable process (milling, 3D printing, casting, or other technologies).

- Quality control and functional verification Before delivery, we verify dimensions, tolerances, and functionality to ensure the reproduced part meets all specifications.

Advantages of BBM’s free reverse engineering

- Recovery of parts no longer on the market or no longer supplied by the original manufacturer.

- Zero initial costs: analysis and quotation are free and without obligation.

- Customization: ability to modify or adapt the part to new requirements.

- Precision and reliability: thanks to modern tools, reproduction is extremely faithful to the original.

- Speed: reduced lead times thanks to digital processes and advanced metrology.

Aspects to consider

Our free reverse engineering service for part reproduction is carried out in full compliance with current intellectual property and component safety regulations. BBM also holds MOCA (Materials and Objects in Contact with Food) certifications, ensuring that components intended for the food industry comply with European food safety standards. This allows us to reproduce parts for machinery in direct or indirect contact with food products, ensuring quality, traceability, and compliance with required standards.

BBM technologies and expertise

To obtain accurate data in reverse engineering, we use state-of-the-art instruments:

- FARO Quantum Max measuring arm: complete dimensional surveys directly on the client’s machine, with exceptional precision and speed. We can measure large or complex-shaped parts both in-house and at the client’s facility, reducing downtime and transportation costs.

- In-house climate-controlled metrology room: designed for high-precision dimensional checks, equipped with digital calipers and micrometers, bore gauges, durometers, roughness testers, profile projectors, and a digital microscope.

- ZEISS machines:

- ZEISS Duramax, a benchmark in precision metrology, allows ultra-high-resolution inspection of medium and large surfaces;

- the new ZEISS optical machine provides extremely fast and precise measurements of small components and hardware.

The combined use of these two machines allows 360° inspection of the part, from the most complex component to the smallest details.

- 3D printing: BBM is introducing a state-of-the-art 3D printer that will allow rapid production of prototypes, jigs, and customized components, shortening development times and optimizing production costs.

Why choose BBM

Relying on BBM means having a partner with over twenty years of experience in the industry, specialized in compatible spare parts for bottling and packaging machines of leading international brands.

Our free reverse engineering service combines:

- high-precision 3D analysis and modeling,

- advanced metrology technologies,

- rigorous quality controls,

- compliance with regulations and MOCA certifications,

- and soon, rapid production via 3D printing.

All of this to provide reliable, safe, and customized components, reducing downtime and costs for the client.