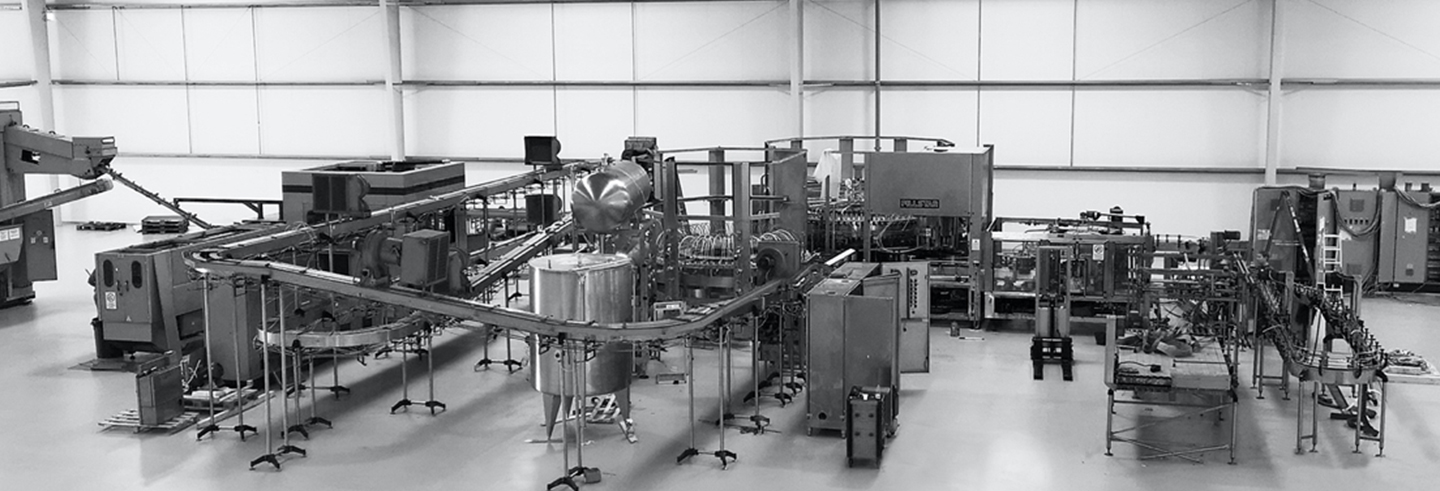

Turnkey relocation service for machines and lines for bottling and packaging lines

What we do

BBM Service offers turnkey relocations for bottling plants and packaging lines, ensuring efficiency, safety, and uninterrupted production. From start to finish, we manage every phase of your project — planning, dismantling, transport, and reassembly — with a single point of contact and clear, transparent management, thus avoiding delays and unexpected issues.

How we work

1. Site inspection and planning

First of all, we evaluate machinery and infrastructure, and then define operational sequences, resources, and equipment needed. During this phase, we plan timelines and budgets together with the client so that transparency is ensured. Additionally, we assign a Project Manager, Site Supervisor, and Safety Officer to coordinate and supervise every step.

2. Preparation and cataloging

Next, we secure operational areas to work safely. Then we share the official project GANTT chart with the client, defining timelines and responsibilities. Afterward, we check lifting and handling equipment, back up machine software and data, and catalog every component in order to guarantee traceability and order. Finally, we plan logistics and transport to ensure smooth machine transfer.

3. Dismantling and overhaul

We carefully dismantle machinery while maintaining safety, and at the same time, we restore work areas for future interventions. During production downtime, we perform inspections and upgrades to enhance efficiency and performance. Machines are then reassembled and tested at the new site. Moreover, we dispose of waste according to environmental regulations, respecting sustainability.

4. Transport and installation

We move machinery using dedicated equipment and qualified personnel. In addition, custom packaging is created to protect equipment during transport. Exceptional transports are managed in collaboration with certified partners. Once machinery arrives at the new site, we provide turnkey installation and assist during start-up, ensuring full operational capacity.

Why choose BBM

- Single point of contact for the entire project

- Safe procedures and qualified personnel

- Timely project delivery and budget compliance

- Dedicated in-house equipment for every movement

- Waste disposal according to CER regulations

- Possibility of machine inspections and upgrades during downtime

Discover our relocation projects

Download presentation

FAQ – frequently asked questions

1. What does the service include?

We cover all phases: technical site inspection, careful dismantling, transport, reassembly, turnkey installation, and final testing. Furthermore, the client has a single point of contact for the entire relocation project.

2. Can I relocate a line within the same plant?

Yes. We manage both internal moves, for example to reorganize production layout, and complete relocations to new facilities. In either case, production downtime is minimized.

3. Which machines do you relocate?

We relocate blow molding machines, fillers, packagers, labelers, handle applicators, palletizers, wrappers, conveyors, and accessories. In addition, we work with plants from SIDEL, KRONES, SMI, OCME, ACMI, KHS, Twinpack, and more.

4. How long does a relocation take?

Duration depends on plant complexity. Therefore, we plan operational phases in advance, sharing an updated GANTT chart. Generally, relocations can take from a few days up to five weeks. Through extra shifts and weekend work, we meet deadlines.

5. Do you offer technical support after relocation?

Yes. We perform inspections, maintenance, and upgrades during and after relocation. Moreover, we assist the client during start-up to ensure full operational capacity.

6. How do you ensure safety?

We assign a Safety Officer and use only certified equipment and qualified personnel, thus guaranteeing that all activities comply with current regulations.

7. Do you handle exceptional transports?

Yes. We use dedicated vehicles and collaborate with specialized partners for exceptional transports, including all necessary permits.

8. How can I request a quote?

Contact our team via the “Contact” form or email info@bbmservice.it. After that, we will schedule a free site inspection and provide a clear proposal with timelines, budget, and operational plan.