PET bottling line format change: work on conveyors and wrapping machine

Optimisation of PET line format change for square bottles: minimum machine downtime and maximum efficiency. Read the case history

Continue readingMaintenance: why “prevention” is the investment that saves your business

Interview with the Service Manager at BBM Packaging: strategies and costs for eliminating downtime

Continue readingThe most requested upgrades by customers for bottling lines

Discover the 6 essential upgrades for major beverage brands - with Daniele Milesi, Director of BBM Service

Continue readingThe daily adventure of a BBM Field Service Technician

Interview with Dario Baldaccini: behind the scenes of the work of a senior travelling technician

Continue readingTechnical Upgrade to the OranSoda PET Packaging Line

Innovative intervention to optimize bottle flow and speed up format changes on the Terme di Crodo line

Continue readingFIUGGI WATER CHOOSES SUSTAINABLE EXCELLENCE: BBM SIGNS TWO BOTTLING LINES

Tradition and innovation come together in an ambitious project: hybrid technologies, sustainability, and automation to lead the iconic Italian brand into the future

Continue readingFrom OUTdated to OUTstanding: how we transformed an obsolete layer pad remover

Independent suction cups, simplified format change, and upgraded pneumatic system for maximum efficiency and reliability

Continue readingHow much does the lack of training for operators on bottling lines cost you?

Discover how the lack of operator training on bottling lines affects efficiency, downtime, and productivity

Continue readingExceptional transport of bottling lines: the case of Acqua Fiuggi

How BBM Packaging faced the logistical challenge of installing two used-reviewed production lines

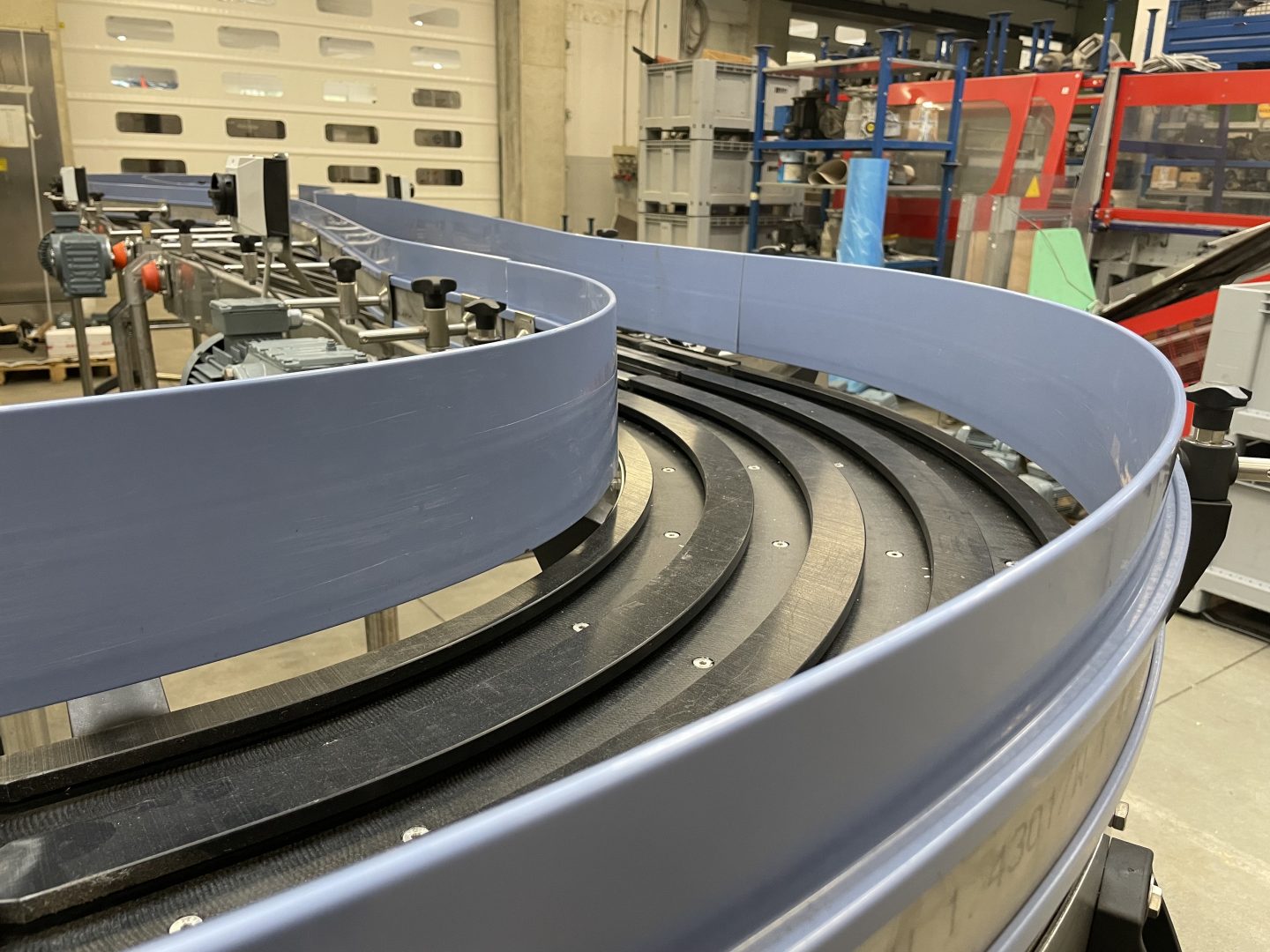

Continue readingRefurbished, used conveyors for beverage bottling plant

Supply and installation of used/revised end-of-line conveyors

Continue reading