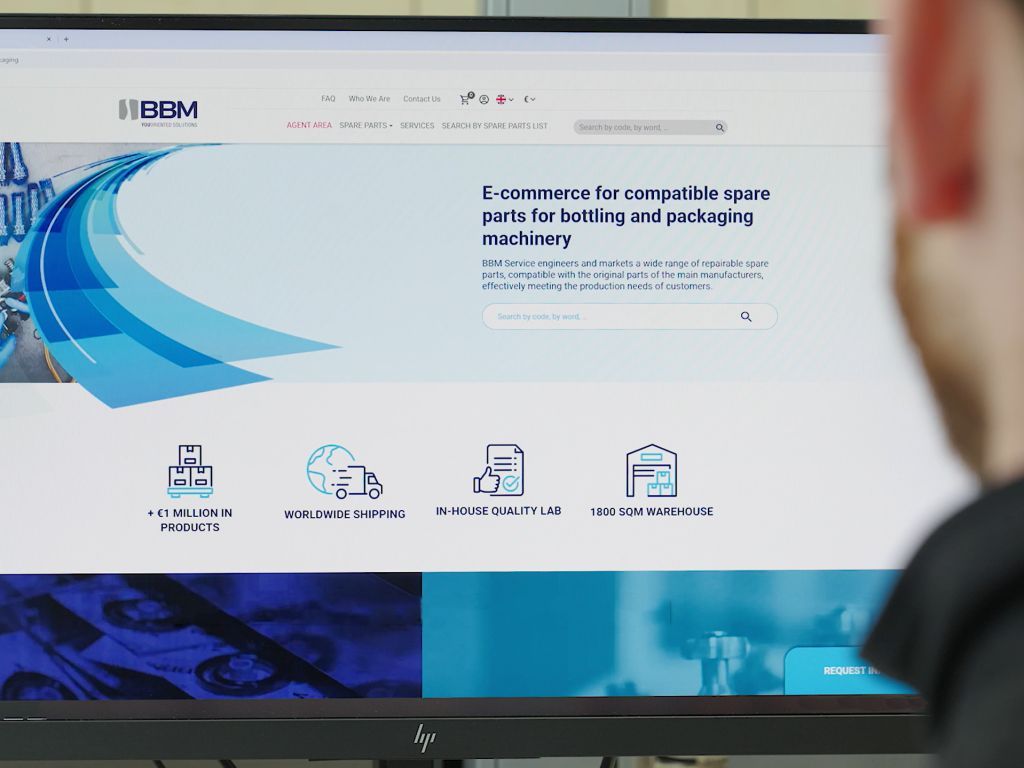

BBM: excellence, Innovation, and Reliability in Bottling and Packaging Spare Parts

At BBM, quality is not just a goal — it is a distinctive mark that sets us apart in the spare parts sector for bottling and packaging machinery. Discover the three pillars of our quality: high standards, long-lasting performance, and uncompromising reliability.

BBM Service supplies compatible spare parts for bottling and packaging machinery used for water, beverages, and food products. To ensure compliance with the highest quality standards, BBM has established a strict quality control process and designed an in-house metrology room equipped with state-of-the-art instruments.

- Rigorous quality control procedure, thanks to the presence of an internal metrology room

- Collaboration with top-tier partners: selected suppliers who perform in-depth analyses on after-market items, in addition to our internal tests. All suppliers are constantly monitored through a vendor rating process

- Drafting of internal compliance reports

BBM Metrology Room: an ideal environment to achieve the highest levels of quality and productivity

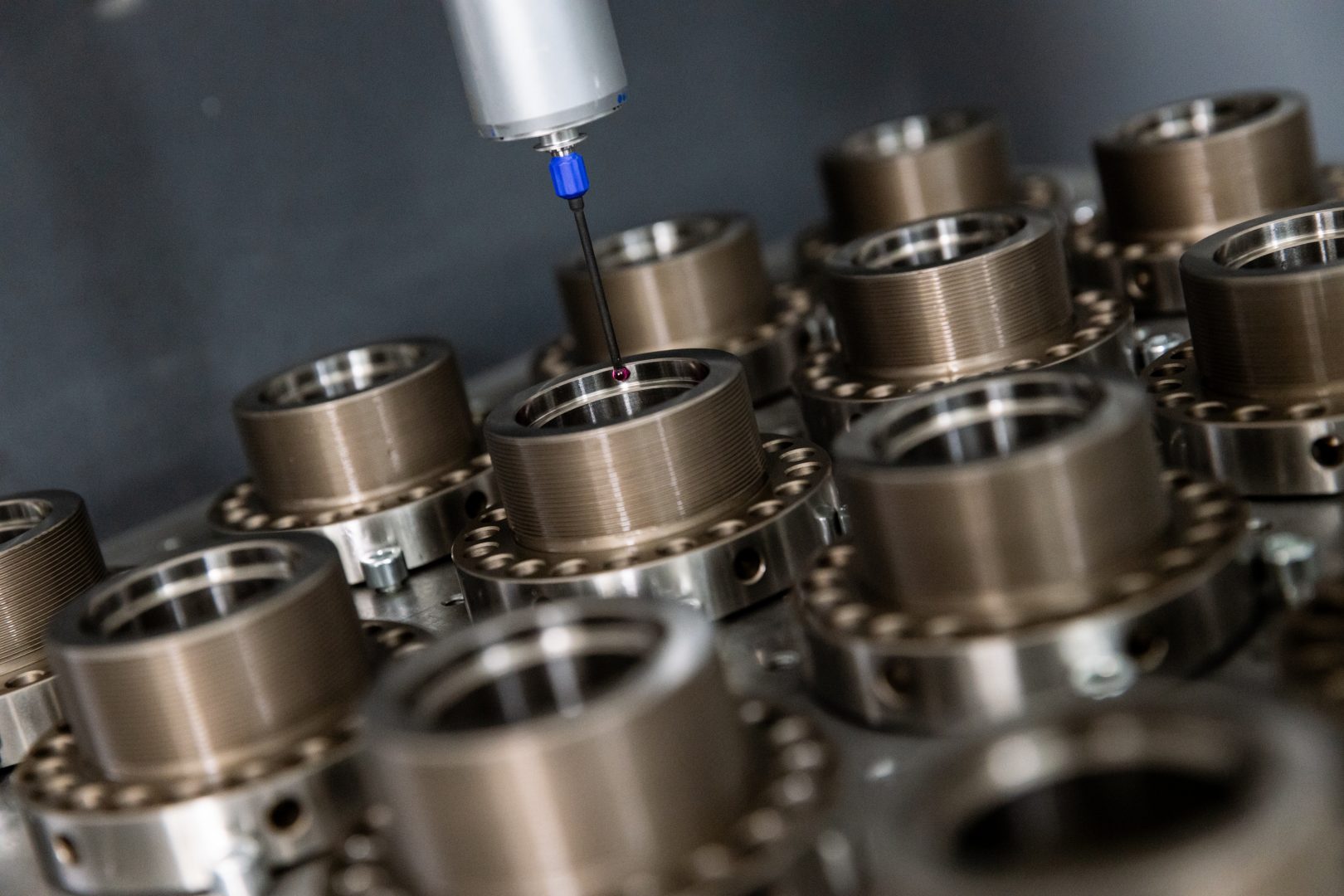

BBM has built a true in-house metrology room. The BBM metrology room is a temperature-controlled, air-conditioned environment equipped with all the tools necessary for high-precision dimensional control. Among the instruments available: large-size digital calipers, external and internal digital micrometers, bore gauges, durometers, roughness testers, profile projectors, digital microscopes, and other devices for the most accurate measurement of part parameters.

Reverse Engineering

Reverse engineering is the process of analyzing a product to understand its structure and design principles, often with the goal of reproducing it — always in compliance with applicable intellectual property laws. Reverse engineering can be used for various purposes, such as improving or correcting an existing product.

With the Quantum Max arm by FARO Technologies, BBM performs complete measurements directly on the customer’s machine. Accurate dimensional detection allows for faithful reproduction of spare parts, including those no longer available on the market. The arm ensures exceptional speed and precision, enabling 3D inspections and rapid defect identification.

Thanks to its portability and 2.5-meter reach, we can perform measurements on large or complex-shaped parts, both at our facility and at the customer’s plant.

ZEISS Scanning Measuring Machine

BBM’s metrology room features its crown jewel: a three-dimensional scanning measuring machine, the ZEISS Duramax — a benchmark brand in precision measurement. Thanks to advanced scanning technology, computer-assisted micron-level precision, high-resolution measurement, and full automation, BBM’s measuring system is unmatched in its category.

New Entry: ZEISS Optical Machine

The brand-new ZEISS optical measuring machine is now operational. Equipped with a high degree of automation and cutting-edge sensors, it enables extremely fast and even more precise measurement of components distributed by BBM.

Thanks to the combined operation of both machines, a 360-degree control of each part is achieved – the first is ideal for measuring medium and large surfaces or complex parts, while the second is perfect for small components and fittings.

Why rely on BBM Packaging quality?

The pursuit of quality is a meticulous process aimed at identifying part weaknesses and resolving them, improving performance and extending lifespan. BBM is a reliable partner for identifying even the most specific part issues, enhancing performance with new treatments and coatings. The ultimate goal? To improve the service life of both the part and the machine.

All BBM spare parts used during bottling line maintenance follow this rigorous process. Only once they are declared suitable are they authorized for shipment and storage.

Continuous Training

BBM invests heavily in training its technical office. Every year, our engineers and designers attend inspiring training sessions at prestigious institutions such as the University of Bergamo – Faculty of Engineering – and the Bergamo Chamber of Commerce. By focusing on key topics such as innovative materials, both metals and plastics, we are committed to ensuring ever-higher quality standards to meet the growing demands of our customers.

Fast and Reliable Response Times

An essential PLUS – Every customer request is handled with maximum speed, without ever compromising quality or accuracy. Discover the efficiency of our logistics infrastructure, which allows us to constantly monitor incoming requests and fulfill orders in the shortest possible time.

Discover BBM’s selection of compatible spare parts

The last news