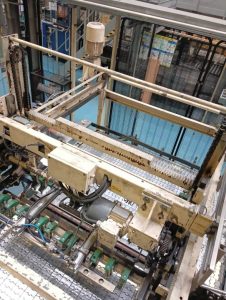

Technical intervention on a layer pad remover for the removal of cardboard and plastic sheets between glass bottles: new pneumatic system, independent suction cups, and simplified format change management

When a system starts showing signs of aging, a complete replacement isn’t always the smartest choice: sometimes, a targeted and strategic intervention is enough to achieve better performance than before. That’s exactly what happened in our latest project involving an automatic layer pad remover, a crucial machine in the initial stages of depalletizing glass bottles.

In this case, the customer had a clear need: increasing difficulty sourcing spare parts and structural components for a heavily worn machine with obsolete elements. We therefore proposed a complete technological upgrade, bringing the machine up to a standard comparable with the latest-generation solutions currently installed on new lines.

What is an automatic layer pad remover and why is it important?

The layer pad remover is an automatic machine used in depalletizing lines to remove the cardboard sheets – the “layer pads” – placed between each layer of product, in this case glass bottles, during pallet disassembly.

Its main function is to progressively free the bottle layers to allow their transfer to the production line, ensuring a continuous and orderly flow of incoming materials.

In practice, each time a layer of bottles is removed, the layer pad remover lifts the top cardboard cover and the underlying plastic interlayer, placing them in a dedicated discharge area.

A seemingly simple system, yet essential for production continuity, operational safety, and proper handling of incoming materials.

The initial issue: limited reliability and downtime

The old system showed clear signs of inefficiency and obsolescence:

- The suction cups were connected to a single vacuum generator (Venturi).

- If even one suction cup failed to grip, the entire system failed the operation.

- Format changes required manual adjustments for every variation.

- Some key structural components were worn out or no longer available.

The result? Frequent line stops, manual interventions, loss of productivity, and increasingly complex maintenance.

Before the intervention on the layer pad remover

Our intervention: simple technology, concrete results

We approached the project with a structured method, aiming to improve reliability and simplify operational management:

- Independent suction cups with dedicated Venturi units

We replaced the old centralized system with individual Venturi units, one for each suction cup.

Advantage: if one suction cup fails to grip properly, the others keep working without losing vacuum. The cycle continues without interruptions. - Simplified and automatic format change

We installed three dedicated photocells, one for each format, already wired into the control panel.

Advantage: selection is made directly from the operator panel. Once the software is integrated into the PLC, the format change will be fully automated. - Upgraded pneumatic system

We rebuilt the system by replacing cylinders and solenoid valves with new, high-performance components.

Advantage: greater operational precision, long-term reliability, and reduced need for maintenance.

The result

We delivered to the customer a technically obsolete machine, now updated with the latest technologies, capable of removing the cardboard cover and interlayer with precision and reliability.

The renewed system:

- Significantly reduces line downtime

- Improves operational flexibility

- Simplifies maintenance activities

The video below shows the new system in action: a concrete example of how a targeted and intelligent modernization can enhance even the oldest machines, improving the entire production process.

Do you need a similar intervention on your system?

Contact us: we can analyze your line and offer you tailored solutions to improve efficiency, safety, and productivity.